Vulcan Energy Resources has announced a significant milestone in its Zero Carbon Lithium Project with the signing of binding contracts with Turboden and ROM Technik for the supply of specialized geothermal energy equipment. The agreement, valued at approximately €21.6 million, marks a crucial step forward for Vulcan’s innovative lithium extraction and renewable energy operations in Germany’s Upper Rhine Valley.

Under the terms of the contract, Turboden, a Mitsubishi Heavy Industrie

...

Vulcan Energy Resources has announced a significant milestone in its Zero Carbon Lithium Project with the signing of binding contracts with Turboden and ROM Technik for the supply of specialized geothermal energy equipment. The agreement, valued at approximately €21.6 million, marks a crucial step forward for Vulcan’s innovative lithium extraction and renewable energy operations in Germany’s Upper Rhine Valley.

Under the terms of the contract, Turboden, a Mitsubishi Heavy Industries subsidiary and global leader in Organic Rankine Cycle (ORC) technology, will supply key geothermal energy equipment including ORC turbines for Vulcan’s Phase One commercial operations. ROM Technik, a division of ROM Group with extensive experience in industrial plant construction across Germany, will provide crucial installation services for the equipment.

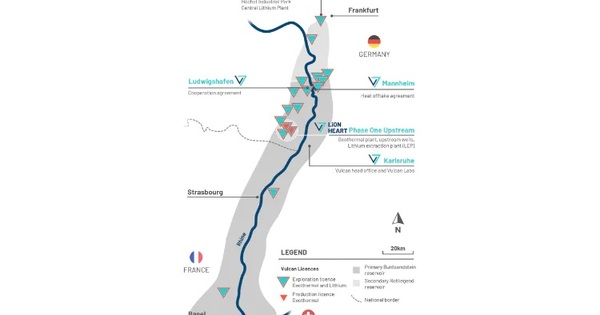

The equipment will be deployed at Vulcan’s Landau and Insheim geothermal renewable energy plants, where geothermal brine will generate renewable electricity while also serving as the source material for lithium extraction. This dual-purpose approach sits at the heart of Vulcan’s Zero Carbon Lithium initiative, which aims to produce battery-grade lithium chemicals with net zero greenhouse gas emissions.

“This contract represents a significant advancement in our Phase One commercial strategy,” said Cris Moreno, Vulcan’s Managing Director and CEO. “By partnering with industry leaders like Turboden and ROM Technik, we’re ensuring our geothermal plants will operate with maximum efficiency and reliability, supporting both our renewable energy production and lithium extraction processes.”

The significance of this development extends beyond Vulcan’s immediate operations. Europe has been aggressively pursuing energy independence and domestic battery material production, particularly in the wake of supply chain disruptions and geopolitical tensions affecting global markets. The European Union has designated lithium as a critical raw material, emphasizing its strategic importance for the continent’s transition to electric vehicles and renewable energy storage.

Vulcan’s project stands out in the emerging lithium sector due to its unique approach. Unlike traditional lithium mining, which typically involves either open-pit mines or evaporation ponds that can have substantial environmental impacts, Vulcan’s process extracts lithium from geothermal brines that are already being pumped from the earth for renewable energy production. After lithium extraction, the brine is reinjected into the reservoir, creating a closed-loop system with minimal environmental disruption.

The Upper Rhine Valley, where Vulcan operates, contains one of Europe’s largest lithium resources. Geological surveys estimate the region holds sufficient lithium to support the production of millions of electric vehicle batteries, potentially making Germany a key player in the battery supply chain. This local production would significantly reduce Europe’s dependence on lithium imports from South America, Australia, and China.

Industry analysts have noted that Vulcan’s progress comes at a critical time for the European automotive sector, which is rapidly transitioning to electric vehicle production. Major manufacturers including Volkswagen, BMW, and Stellantis have all announced ambitious electrification plans, creating substantial demand for battery materials.

Vulcan has already secured offtake agreements with several high-profile customers, including Volkswagen Group, Stellantis, Renault Group, and battery manufacturer LG Energy Solution. These agreements underscore the strong market demand for sustainably produced lithium with minimal carbon footprint.

“The European battery supply chain is developing rapidly, and securing low-carbon raw materials is a priority for manufacturers,” explained Martin Schimmel, an industry analyst at Battery Materials Research Institute. “Vulcan’s approach addresses both the need for domestic lithium production and the increasing pressure to reduce the carbon footprint of electric vehicles.”

The financial terms of the Turboden and ROM Technik contracts include a payment schedule aligned with equipment delivery milestones, with initial payments scheduled for 2024 and the majority of equipment expected to be delivered in 2025. Vulcan indicated that the contracts remain subject to customary conditions precedent, including the final investment decision for Phase One, anticipated in mid-2024.

Vulcan’s broader Phase One development encompasses multiple geothermal wells, a central lithium extraction plant, and a central lithium electrolysis and processing plant. When operational, the company expects to produce approximately 24,000 tonnes of lithium hydroxide annually while generating renewable electricity.

This latest contract announcement follows Vulcan’s recent progress in obtaining regulatory approvals and completing successful pilot operations that have validated the company’s technical approach to lithium extraction from geothermal brines.

As Europe accelerates its transition to a carbon-neutral economy, projects like Vulcan’s Zero Carbon Lithium initiative represent an emerging model for how critical materials can be produced with minimal environmental impact, potentially reshaping supply chains for the clean energy transition.