Mining operations and electronics manufacturing sectors have gained a new tool for high-precision bonding with the introduction of Master Bond’s LED422DC90, an innovative dual-cure adhesive system that promises to revolutionize assembly processes for heat-sensitive components in demanding environments.

The newly developed adhesive stands out for its unique “side-bonding” capability, which enables rapid polymerization of opaque substrates up to 3-4 mm in depth. Unlike convention

...

Mining operations and electronics manufacturing sectors have gained a new tool for high-precision bonding with the introduction of Master Bond’s LED422DC90, an innovative dual-cure adhesive system that promises to revolutionize assembly processes for heat-sensitive components in demanding environments.

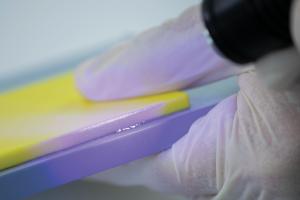

The newly developed adhesive stands out for its unique “side-bonding” capability, which enables rapid polymerization of opaque substrates up to 3-4 mm in depth. Unlike conventional adhesives that require direct light exposure, LED422DC90 can be cured by applying 405 nm LED light from an angle, followed by a secondary heat cure at 90-95°C for 30-45 minutes. This two-stage curing process provides manufacturers with unprecedented precision when working with temperature-sensitive materials.

Industry analysts note that this development comes at a critical time when mining equipment manufacturers are seeking more durable joining solutions that can withstand extreme conditions while maintaining structural integrity. The adhesive’s NASA low outgassing certification further positions it as a suitable option for specialized equipment used in confined mining environments where gas emissions are a significant concern.

The technical specifications of LED422DC90 highlight its suitability for harsh industrial applications. With a Shore D hardness of 85-90, the adhesive delivers exceptional durability while maintaining a modest elongation of 1-3%. Its tensile strength ranges from 6,000-7,000 psi, with a tensile modulus of 475,000-575,000 psi, making it capable of withstanding significant physical stress in operational environments.

For equipment manufacturers in the mining sector, the adhesive’s thermal properties are particularly valuable. LED422DC90 exhibits good dimensional stability with a relatively low coefficient of thermal expansion (30-40 x 10^-6 in/in/°C), allowing bonded components to maintain their integrity across temperature fluctuations common in mining operations. The adhesive remains serviceable across an impressive temperature range from -80°F to +350°F, addressing the diverse climate conditions encountered in global mining sites.

The product’s electrical insulation properties also offer significant advantages for electronics integrated into mining equipment. With a volume resistivity exceeding 10^14 ohm-cm, LED422DC90 provides reliable protection against electrical interference in sensitive monitoring and control systems that are increasingly common in modern mining operations.

Material compatibility represents another strength of the new adhesive. Engineering teams can apply LED422DC90 across various substrate materials including plastics, glass, and metals—materials commonly found in mining equipment assemblies. For aluminum-to-aluminum applications, the adhesive delivers a tensile lap shear strength of 800-900 psi, ensuring secure bonds in structural components.

The optical clarity of LED422DC90, with its refractive index of 1.49, also makes it suitable for applications involving sensors and optical monitoring equipment used in modern mining operations. This characteristic allows for the bonding of transparent components without compromising visual or sensor-based monitoring capabilities.

Market observers expect the adhesive to find applications beyond mining in adjacent industries including aerospace and general electronics manufacturing, where its combination of mechanical strength, thermal stability, and specialized curing process offers solutions to longstanding assembly challenges.

The adhesive is available in various packaging options including EFD® syringes, ½ pint, pint, and quart containers, providing flexibility for different scales of manufacturing operations from small repair applications to large-scale equipment production.

As mining operations continue to advance technologically with more sophisticated equipment, specialized materials like LED422DC90 represent an important development in the industry’s supply chain, enabling equipment manufacturers to deliver more durable and reliable products for challenging extraction environments.